Clean ship innovation

Correct & economic application

Continuous support and monitoring

제휴업체

AFFLIATESNyborg A/S

- HOME

- 제휴업체

- Nyborg A/S

APPLICATIONS

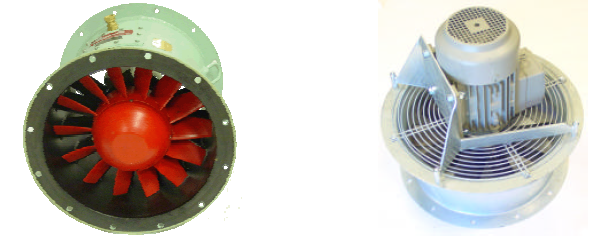

The Nyborg axial fans are heavy duty fans designed for marine applications. The fans are delivered in sizes from ø250 to ø1600 with capacities up to 200.000 m3/h and static pressures up to 1600 Pa.

EXECUTION

The MPV fans are heavy duty fans designed for marine applications, manufactured in mild steel, hot dip galvanized.

OPTIONAL EXECUTION

Fan in stainless steel execution (aisi304/316)

Fan in alum execution,

IMPELLER:

The MPV fans are made in two versions with two different impellers:

MPV-A1 ? with A impeller for fan without guide vanes

A simple and robust design often makes this the most cost effective alternative. The impeller is made of sea water resistant alum and is cast id one unit and has a high reversible capacity (approx 60% of normal capacity). The model is most suitable for high air volumes and low to medium/moderate pressures. The fan with the A impeller also have a small “stall” area.

For sizes from ø250 up to ø500mm the fan can be delivered with an impeller made of reinforced polypropylene. with variable pitch.

MPV ? D1

With D impeller for fan with guide vanes:

The axial fans with the D impeller is equipped with guide vanes for higher pressures and efficiency. The impeller is made of sea water resistant alum and has variable pitch to easier suit different capacities and pressures.

Due to the guide vanes the fan can achieve pressures up to 1600 Pa.

CASING

The MPV fan is made in four models

l MPV ? A1K/D1K ? tube fan for installing in duct or end of duct, with inspection cover and cable glands in casing

l MPV ? A1E/D1E ? for duct connection / duct end installation. The fan is with short casing and inlet cone for better performance. The motor is outside of the casing for easy accessability. As standard a protection grid is fitted to the fan.

l MPV ? A1B ? for wall mounting The fan is with inlet cone for smaller pressure drop and better performance and is delivered with a protection grid (wire guard) as standard.

l MPV ? A1M/D1M ? for installing in duct or duct end. The fan is a swing out construction where motor and impeller can be swung out for maintenance (and inspection).

ELECTRIC MOTOR

The motors are as standard TEFC squirrel caged inductive electric motors in marine execution. Motors are IP55 and insulation class F as standard. The fans can also be equipped with EX motors class Exe (increased safety) , Exd or Exde (explosion-/flameproof) or EXN motors.

Motor options:

l IP56, IP65 or IP66,

l anti condensing heating element

l offshore painting

l Vibration monitoring

SPECIAL DESIGNS

l Spark proof execution/design with anti spark track

l Thick casing, 6, 8 or 10mm thickness

l Short casing (MPV ? A1K/D1K)

l special bolt division circle

l fan with guide vanes before and after impeller for extra high pressures

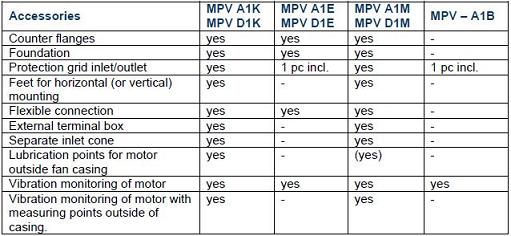

ACCESSORIES