Clean ship innovation

Correct & economic application

Continuous support and monitoring

제휴업체

AFFLIATESOILON

- HOME

- 제휴업체

- OILON

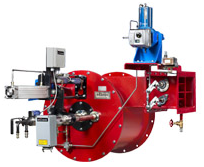

Power Plant and Process Burners

1. LENOX Low-NOx burners

Lenox is designed for power plant boilers fulfilling the stringent emission requirements.

This achievement of technology is based on staged combustion.

Fuel is lead into different zones of the flame. Combustion air is divided into individually controlled chambers in wind box and directed also in stages to the flame. These fuel and air flows cause optimal air envelopes inside and around the flame resulting in long residence time and low emissions. If the requirements of emission levels are very demanding, flue gas recirculation is an option to Lenox.

2. S-burners for various applications S-burner is typically used in hot water and steam boilers, but is suitable also in various further applications. The amount and ratio of primary and secondary air can be adjusted. Secondary air is guided through adjustable air vanes, which enables the formation of the desired flame shape and thus matching optimally to the furnace dimensions. Additionally, the adjustability contributes to achieving the required emission levels in different furnace sizes and forms. By request, S-burner is capable to be provided with single or dual-fuel liquid lance, gas lance and gas ring.

3. K-burners for different kind of processes K-burner is the right choice for many different types of industrial processes, for example in hazardous waste and municipal waste incineration plants. The combustion air inlet is located eccentric on one side of the burner guiding the combustion air tangentially to the wind box, which causes a strong swirl and stable flame. The burner construction is designed for heavy duty operation to guarantee good availability in extreme process conditions. K-burner can be equipped with several lances according to the number of different fuels.

4. Lance burners for demanding purposes Lance burner presents technology to different demanding industrial purposes, for example as start-up and support burner in fluidized bed boilers. It is essential, that the parts will tolerate the effects of the sand bed. This is achieved in lance burner by optimized cleaning and cooling air flow through the burner. When the burner is stand-by, the critical parts will be retracted automatically. The small diameter of the lance burner allows to minimize burner openings on the boiler walls.